Fixing a Wonky Trident Bed Mesh

The Problem

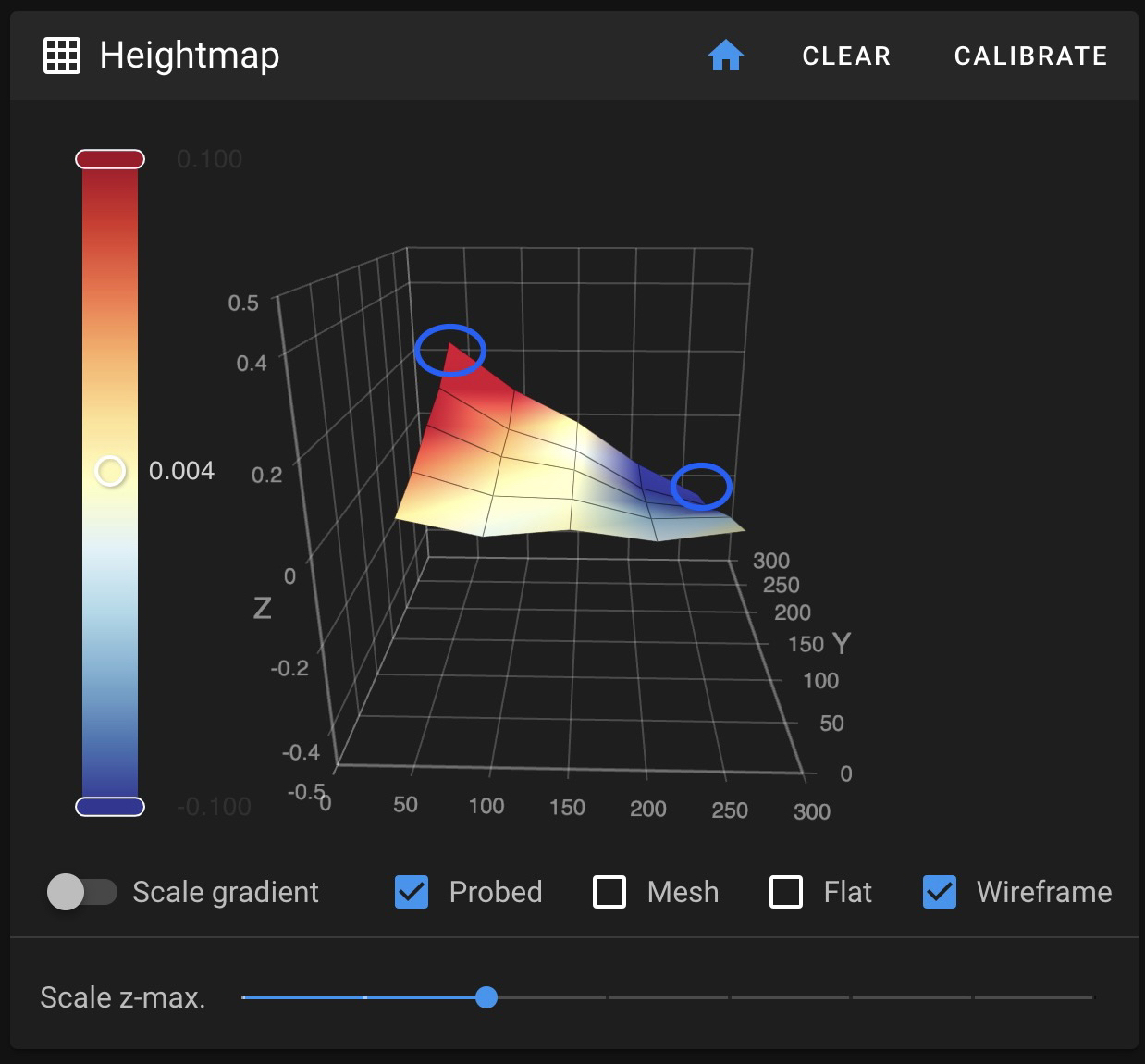

Y extrusions that are not in plane with each other result in an odd mesh. It will appear straight across the front of the bed and the back will have a slant.

This is because a Trident only levels the bed from 3 points near the Z drives so it does not have the means to correct Z height in the back corners.

Identifying the Issue

Run a bed mesh and look for this pattern:

- Front of the bed appears level (straight line)

- Back of the bed shows a slant

- One back corner will appear red in the mesh visualization

This image shows an example of the wonky mesh and indicates the two points that should be measured:

Fixing the Issue

-

Prepare: Place the printer in its permanent location and ensure the surface it’s on is flat and solid.

-

Measure: With a mesh active, hover over the two back corner points and see the difference in Z height between them. This difference is the amount you need to adjust.

-

Adjust: On the side that is red (looks too high), you will adjust the front corner down by the amount measured in step 2. This is done by loosening the screw for the blind joint on the front of the printer in the vertical extrusion. Move that side of the Y extrusion down.

-

Verify: Leave the printer powered and leveled while making these adjustments so you can quickly run a Z-Tilt and a bed mesh to see if further adjustment is required.